Airless support

Find your Airless size

Tannus Airless tires are compatible with clincher rims but not with tubular rims.

To evaluate compatibility, follow the steps below.

Find your Airless size

Tannus Airless tires are compatible with clincher rims but not with tubular rims.

To evaluate compatibility, follow the steps below.

1) Measure the inner channel of the rim

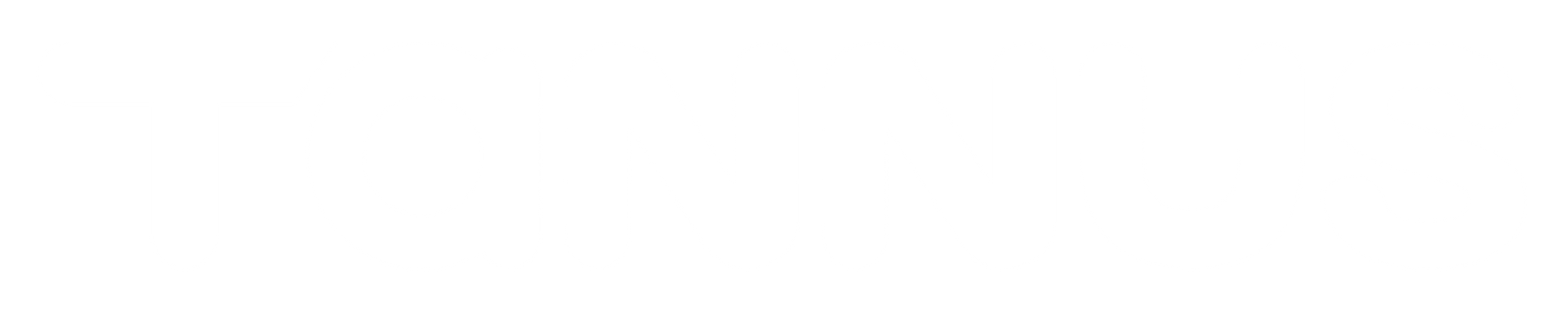

To find out the width of the inner channel of the rim there are two ways:

1) Identify the ETRTO measurement on the rim. The ETRTO measurement is shown on the rim stickers with two numbers.

Example: 622-15C. The number 15 corresponds to the millimeters of the internal channel of the rim.

2) Remove the tire and measure the inside of the channel with a caliper or ruler (as shown).

2) Select the correct size of Tannus Airless

Based on the size of your rim and the width of the internal channel, consult the table and find out which tire is best suited to your rim.

Remember that it is essential to have a rim with an internal channel corresponding to that shown in the table. Even a millimeter of difference can make assembly impossible.

| AIRLESS | ETRTO | INTERNAL RIM CHANNEL * (mm) | EQUIVALENT PRESSURE (Atm)** | WEIGHT (g) |

|---|---|---|---|

| 16/18x1.25 (32-349) BROMPTON | 17-20 | 6 | 310 |

| 20x1.25 (32-406) MINI VELO | 17-20 | 6 | 360 |

| 20x1.5 (40-406) SHIELD | 19-21 | 5,5 | 570 |

| 22x1 3/8 (35-501) WHEELCHAIR | 18-20 | 4,1 | 390 |

| 24x1.00 (25-540) WHEELCHAIR | 18-20 | 7,2 | 410 |

| 24x1 3/8 (35-540) WHEELCHAIR | 18-20 | 4,1 | 460 |

| 24x1.75 (44-507) SHIELD | 19-21 | 5,5 | 670 |

| 26x1.75 (44-559) RAZORBLADE | 17-20 | 4,6 | 800 |

| 26x1 3/8 (35-590) SHIELD | 18-20 | 4,4 | 620 |

| 700x23C (23-622) SLICK | 13-15 | 7,8 | 370 |

| 700x25C (25-622) NEW SLICK | 16-18 | 7,8 | 434 |

| 700x28C (28-622) SEMI SLICK | 14-16 | 7,2 | 460 |

| 700x28C (28-622) PORTAL | 19-21 | 7,2 | 490 |

| 700x32C (32-622) SHIELD | 18-20 | 4,4 | 650 |

| 700x40C (40-622) SHIELD | 19-21 | 4,4 | 730 |

* Parameter of fundamental importance for proceeding with the assembly of Tannus Airless

** The pressure, as there is no air in the conventional way, is to be referred to the sensation of an equivalent pressure in traditional tyres

Based on the size of your rim and the width of the internal channel, consult the table and find out which tire is best suited to your rim.

Remember that it is essential to have a rim with an internal channel corresponding to that shown in the table. Even a millimeter of difference can make assembly impossible.

| AIRLESS | ETRTO | INTERNAL RIM CHANNEL * (mm) | EQUIVALENT PRESSURE (Atm)** | WEIGHT (g) |

|---|---|---|---|

| 16/18x1.25 (32-349) BROMPTON | 17-20 | 6 | 310 |

| 20x1.25 (32-406) MINI VELO | 17-20 | 6 | 360 |

| 20x1.5 (40-406) SHIELD | 19-21 | 5,5 | 570 |

| 22x1 3/8 (35-501) WHEELCHAIR | 18-20 | 4,1 | 390 |

| 24x1.00 (25-540) WHEELCHAIR | 18-20 | 7,2 | 410 |

| 24x1 3/8 (35-540) WHEELCHAIR | 18-20 | 4,1 | 460 |

| 24x1.75 (44-507) SHIELD | 19-21 | 5,5 | 670 |

| 26x1.75 (44-559) RAZORBLADE | 17-20 | 4,6 | 800 |

| 26x1 3/8 (35-590) SHIELD | 18-20 | 4,4 | 620 |

| 700x23C (23-622) SLICK | 13-15 | 7,8 | 370 |

| 700x25C (25-622) NEW SLICK | 16-18 | 7,8 | 434 |

| 700x28C (28-622) SEMI SLICK | 14-16 | 7,2 | 460 |

| 700x28C (28-622) PORTAL | 19-21 | 7,2 | 490 |

| 700x32C (32-622) SHIELD | 18-20 | 4,4 | 650 |

| 700x40C (40-622) SHIELD | 19-21 | 4,4 | 730 |

* Parameter of fundamental importance for proceeding with the assembly of Tannus Airless

** The pressure, as there is no air in the conventional way, is to be referred to the sensation of an equivalent pressure in traditional tyres

How to assemble Airless

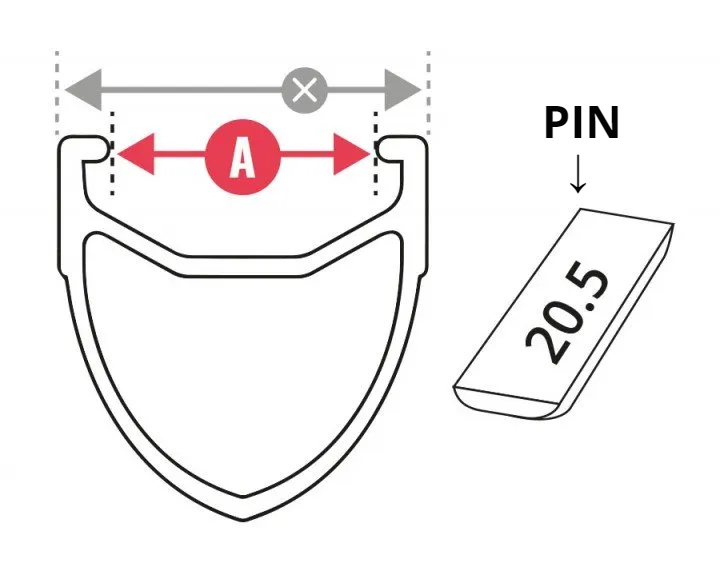

Each package of Airless contains 3 different sizes of PIN and the S-Tool assembly tool.

Select Correct PIN

PIN selection Correct

Disassembly

FAQs Airless

PRODUCT

-

Is Airless an insert?

Tannus Airless are not inserts. They are solid tires so they act as both an inner tube and a tyre.

-

What are Airless tires made of?

Tannus tires are made of a material called Aither. Both the material and the anchoring system are patented worldwide. It is a constantly evolving material. You can find more specifications on the Aither 1.1 page.

-

Are there any differences with traditional tyres?

Unlike other solid tires, Tannus has made impressive technological advances that make the tires lightweight, comfortable and durable. Most people don't notice a difference when they use Tannus Airless, except that they no longer get flats and don't have to check their tire pressure every time.

-

They're heavy?

The weight increases by approximately 20-50 grams per tire on average compared to the most popular solutions on the market. It is equivalent to a quarter of the weight of the spare tube.

-

Are they good for offroad?

They are mainly designed for roads and dirt roads. For more extreme stuff, check out Tannus Armor.

-

How long they last?

The life of the Tannus Airless depends on several factors such as terrain and driving. Tannus guarantees you a minimum duration of 6,000 km but they tend to last around 9,000 km.

-

How roadworthy are they? and in the wet?

Road holding is comparable to traditional tyres. Think about it, they wouldn't have been certified by TÜV if this wasn't the case. Even on wet surfaces and at high speeds, Tannus Airless will always support you.

-

Do you need a particular rim?

Absolutely not. Tannus Airless mounts on all rims except tubular rims and hockless rims.

-

Recommended maximum weight?

The maximum weight we recommend for Tannus tires is to be kept under 150kg for the pair, therefore 75kg per tyre.

-

Do you have NON fare with Tannus Airless?

Even if it is a solid tire and you eliminate the problem of punctures and lateral bead breaking, it is still a polymer-based tire. Therefore skids could shorten the useful life of the product.

-

What are the characteristics of Tannus Airless treads? What do traditional covers look like?

There are 5 different tread styles. In order of tread depth: Slick -> New Slick -> Semi-Slick -> Shield -> Razorblade -> Mini-Velo

-

Do the tires have heat problems?

The reaction of Tannus tires to the heat is no different than a normal tyre. Think about it, when was the last time the soles of your shoes melted? Since they are made of the same polymer base as the soles of sneakers, the reaction with heat is the same. Test with heat? Approved.

COMPATIBILITY

COMPATIBILITY

-

Do you need a particular rim?

Absolutely not. Tannus Airless mounts on all rims except tubular rims and hockless rims.

-

How do I evaluate the right size?

Absolutely not. Tannus Airless mounts on all rims except tubular rims.

-

Recommended maximum weight?

The maximum weight we recommend for Tannus tires is to be kept under 150 kg for the pair.

-

Do you have NON fare with Tannus Airless?

Even if it is a solid tire and you eliminate the problem of punctures and lateral bead breaking, it is still a polymer-based tire. Therefore skids could shorten the useful life of the product.

-

What are the characteristics of Tannus Airless treads? What do traditional covers look like?

There are 5 different tread styles. In order of tread depth: Slick -> New Slick -> Semi-Slick -> Shield -> Razorblade -> Mini-Velo

-

Do the tires have heat problems?

The reaction of Tannus tires to the heat is no different than a normal tyre. Think about it, when was the last time the soles of your shoes melted? Since they are made of the same polymer base as the soles of sneakers, the reaction with heat is the same. Test with heat? Approved.

ASSEMBLY

-

Is Tannus Airless difficult to install? How long does it take?

It depends on you and your manual skills. Approximately it takes 20-40 minutes per tire depending on the size of the tire. Wider tires are more difficult to install but are not impossible. Here are some tips to make it easier:

-

What do I need for assembly?

With the tire you will receive everything you need (instructions, pin and lever) you don't need anything else.

-

The most important part of the assembly?

The choice of PINs is the key to the assembly process. In the assembly kit you should find 3 different sizes of PINs with 3 different colors. To choose the one that best suits your tire, visit the Pin Sizes page.

-

How can I measure the width of the inner rim channel?

For this we have 3 ways:

-

PIN entry tips

Push the Pins with your fingers using a rag or gloves to avoid cutting yourself. Then complete the work with the P-tool included in the box.

-

What happens if the PIN holes are blocked?

Despite hand-made quality control, these small defects may happen during production. This does not damage the tires or compromise safety and fitment. You simply have to push the PIN with more force or first pierce the rubber layer that blocks it.

-

How do I make sure the PIN is entered correctly?

You shouldn't see any PINs exposed. If you look at the tire at the end of the assembly, you should only see the cut-out half-moon of the tire above each PIN but not the plastic PIN.

-

Two PINS fit into the circle, one is loose and one is tight. Which one should I use?

Always the narrow one. In this way safety is maximum and lateral bead breaking is eliminated.

Tannus Newsletter

Sign up for the newsletter and receive a 10% discount code

USEFUL LINKS

SUPPORT

RETAILERS

Sign up for the newsletter and receive a 10% discount code